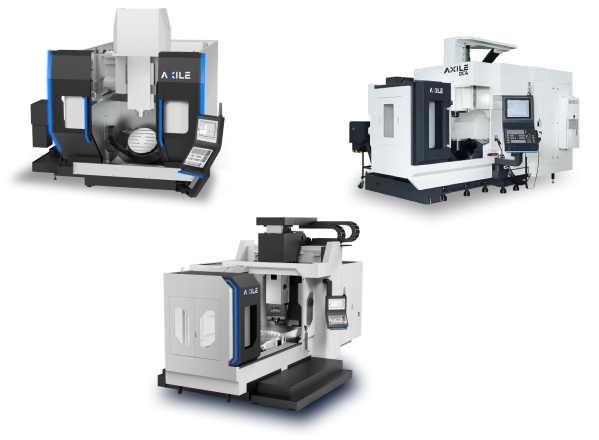

AXILE – High Precision 5 Axis Vertical Machining Center

AXILE’s agile smart 5-axis Vertical Machining Centers (VMCs) are designed and built to support manufacturers of complex parts and components in adopting Industry 4.0, fostering a sustainable business model. The integration of leading digitalized automation solutions is at the core of these machines.

Within each AXILE 5-axis machine, ultra-high removal rates and precise accuracy are achieved through the combined expertise of industry specialists. Additionally, production reliability 24/7 is ensured by the proprietary ART™ intelligent monitoring system.

Manav Marketing provides sales and service support for these high end 5 axis machines in the whole of South India.

Products

Edit Content

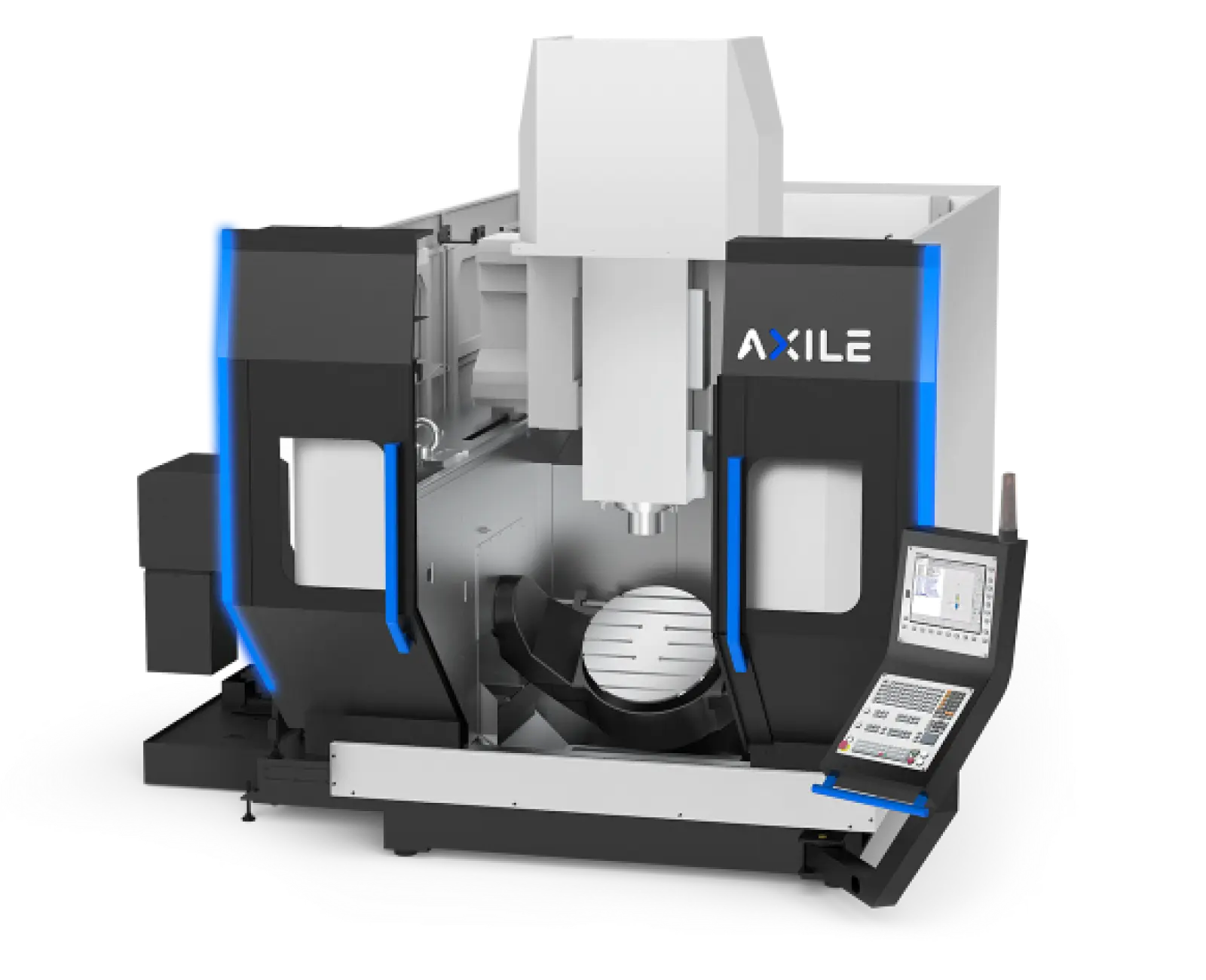

G6

The G6’s ideal blend of speed and precision makes it a prime choice for job shops and production lines aiming to enhance their machining capabilities. It offers high material removal rates, superior surface finishes, and optimal production efficiency.

Features and Specifications

- High-performance built-in spindle

- Table moved by swivelling-rotary axes

- Perfect U-shape closed-gantry design

- Linear scales in all guideways

- Rotary table diameter: G6 — 600 mm; G6 MT — 500 mm

- Max table load: G6 — 600 kg; G6 MT — 350 kg (Turning), 500 kg (Milling)

- Max X, Y, Z axis travel: 650, 850, 500 (mm)

- Spindle speed: 20,000 rpm (Standard) or 15,000 rpm (Option)

- Compatible CNC controllers: Fanuc, Heidenhain, Siemens

Edit Content

G8

The G8’s swivelling rotary table, which can handle loads of up to 1,300 kg, along with high-performance built-in spindles, makes it agile enough to produce a diverse array of large parts and tools.

The G8 MT model provides milling and turning within a single machine, significantly enhancing operational flexibility. By minimizing set-up times and reducing the likelihood of clamping errors, the G8 MT can efficiently process a broader range of parts, including cylindrical components.

Features and Specifications

- High-performance built-in spindle

- Table moved by swivelling-rotary axes

- Perfect U-shape closed-gantry design

- Linear scales in all guideways

- Rotary table diameter: 800 mm

- Max table load: G8 – up to 1,300 kg ; G8MT – up to 850 kg (Turning) / 1,200 kg (Milling)

- Max X, Y, Z axis travel: 670, 820, 600 mm

- Spindle speed: 20,000 rpm (Standard) or 15,000 rpm (Option)

- Compatible CNC controllers: Fanuc, Heidenhain, Siemens

Edit Content

DC4

The DC4 is AXILE’s new 5-axis best work, featuring a 400 mm table and a machine structure that achieves an optimal balance of speed, rigidity, and accuracy. The design of the DC4 brings the spindle closer to the machine’s center of mass, enhancing rigidity and providing exceptional stability. This configuration minimizes vibrations and ensures precise machining, even at high speeds or when working with tough materials. This platform is ideal for applications in aerospace, medical fields, and the die and mold industry.

Features and Specifications

- Table moved by tilting rotary axes

- Integrated roof with overhead crane for easy loading

- Easy access to work area for ergonomic workpiece preparation and supervision

- Clear visibility to monitor machining process

- Bridge structure design means tougher rigidity for handling larger, heavier parts

- Rotary table diameter: 400 mm

- Max table load: 300 kg

- Max X, Y, Z axis travel: 945, 670, 400mm

- Spindle speed: 20,000 rpm/36,000rpm

- Compatible CNC controllers: Fanuc, Heidenhain, Siemens

Edit Content

DC12

The DC12 stands out as the most durable Vertical Machining Center (VMC) in AXILE’s lineup, designed to accommodate larger, elongated workpieces. With a table that can bear up to 2.5 tonnes and support pieces with a maximum diameter of 2,200 mm by 1,200 mm, the DC12 is engineered for large and heavy components typically used in the aerospace, power generation, and die and mold industries. Its double-column bridge design provides enhanced rigidity and better control of thermal deformation, allowing the DC12 to handle deep cuts and intricate contouring while maintaining high precision.

Features and Specifications

- Swivelling high-performance spindle ideal for complex part features

- Integrated roof with overhead crane for easy loading

- Easy access to work area for ergonomic workpiece preparation and supervision

- Clear visibility to monitor machining process

- Bridge structure design means tougher rigidity for handling larger, heavier parts

- Rotary table diameter: 1,200 mm

- Max table load: 2,500 kg

- Max X, Y, Z axis travel: 2,200, 1,400, 1,000 mm

- Spindle speed: 20,000 rpm (Standard) or 16,000 rpm (Option)

- Compatible CNC controllers: Fanuc, Heidenhain, Siemens

In case of any enquiry, leave a message

Address

No. 185/A-1/1, 7th Main Road, Yeshwanthpur Suburb 2nd Stage, Phase -3, Peenya, Bengaluru – 560058