Mikron – High End Transfer Machines

Mikron is known for manufacturing high precision, productive and automated solutions, cutting tools and machining systems. Over 100 years of experience, state-of-art technologies have made Mikron the global leader in their industry. They are based of out Switzerland and their additional production sites includes Germany, US etc.

Manav Marketing is the authorized distributor and service provider of Mikron Switzerland AG Transfer machines in India.

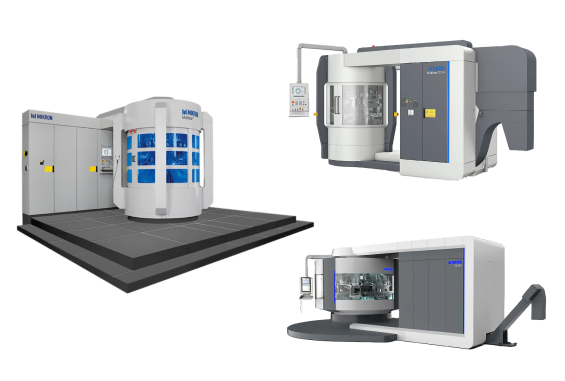

Products

-

Multistep XT 200

-

Mikron MultiX

-

Mikron Multistar CX 24

-

Mikron Multistar LX 24

-

Multistar NX 24

-

Mikron NRG-50

Edit Content

Multistep XT 200: Cost Effective and High Precision

The Multistep XT-200 modular high-precision machining center stands out as an exceptional productivity system!

Its unparalleled modularity and flexibility are highlighted by the capability of up to 4 independently operating spindles and the availability of up to 144 tools, ensuring outstanding versatility. An optional high-frequency spindle caters to high-speed machining needs.

The Multistep XT-200 can be upgraded with additional machining modules (ranging from 1 to 4) to accommodate future production increases with unmatched precision, eliminating the need for an extra loading/unloading module.

Features and Specifications

- Fully modular machining center with 1-4 machining modules for workpiece dimensions of up to 200 x 200 x 200mm

- Full 5-axis CNC machining

- Chip-to-chip time 0.9 seconds at a maximum spindle speed - saving up to 2000 hours per year

Edit Content

Mikron MultiX

Platform For Dedicated Easy Reconfigurable Machining Solution.

Discover unparalleled productivity with Mikron MultiX, the groundbreaking rotary transfer machine acclaimed for its remarkably adaptable technical capabilities!

Features and Specifications

- Flexible Configuration for Specific Needs

- Simple Reconfiguration

- Definite Technical Features

- Different Machining Units for Range of Sizes

- Three Different Machine Layouts

Edit Content

Mikron Multistar CX 24

Precision, Speed, And Versatility For High-Volume Production.

Parts which require perfect processing with serial production can be carried out hassle free in the Multistar CX-24. It is known for its high precision, customization, rapids and versatility. Simply the best in class.

Features and Specifications

- Serial Production of Workpieces with High Precision

- ± 2.5 µm Table Index Repeatability

- 24 Stations with Up To 44 Machining Units Allow Very High Output Rate

- Three Different Machine Layouts

Edit Content

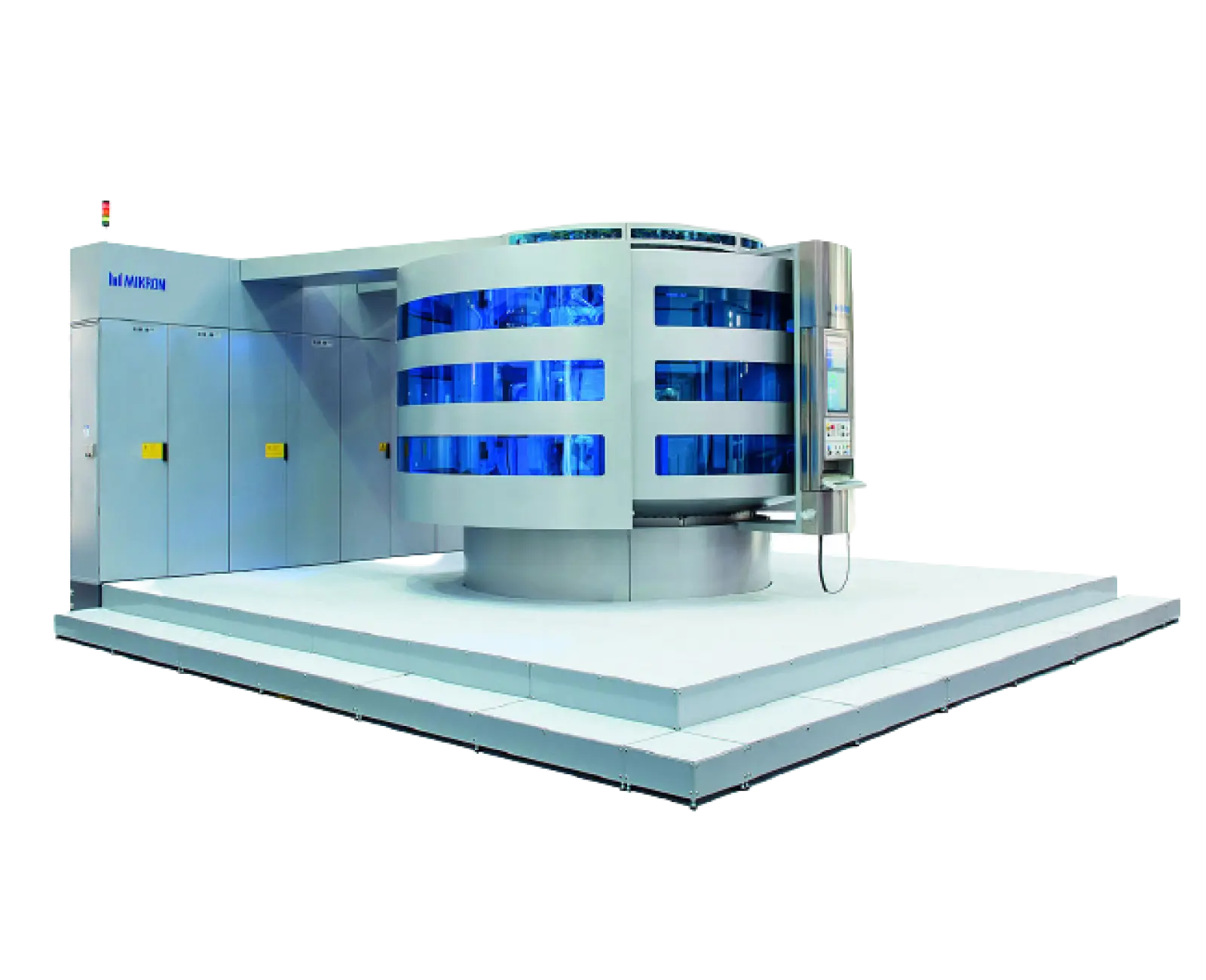

Mikron Multistar LX 24

World’s Fastest Rotary Transfer machine for high-volume production.

Multistar LX enables precision manufacturing of small parts in large quantities. The Multistar LX is a dependable partner thanks to its quick, nimble, and precise performance, as well as its simple and efficient design.

Features and Specifications

- Additional 24 intermediate stations for measuring, controlling and cleaning on request

- Up to 44 work spindles

- Can produce up to 600 simple parts per minute

- Ideal for production of at least one million parts per year

- Work area separation doubles, triples or quadruples production rate

- Machining can be performed from below, above or from the side, e.g. for drilling, turning or thread cutting

Edit Content

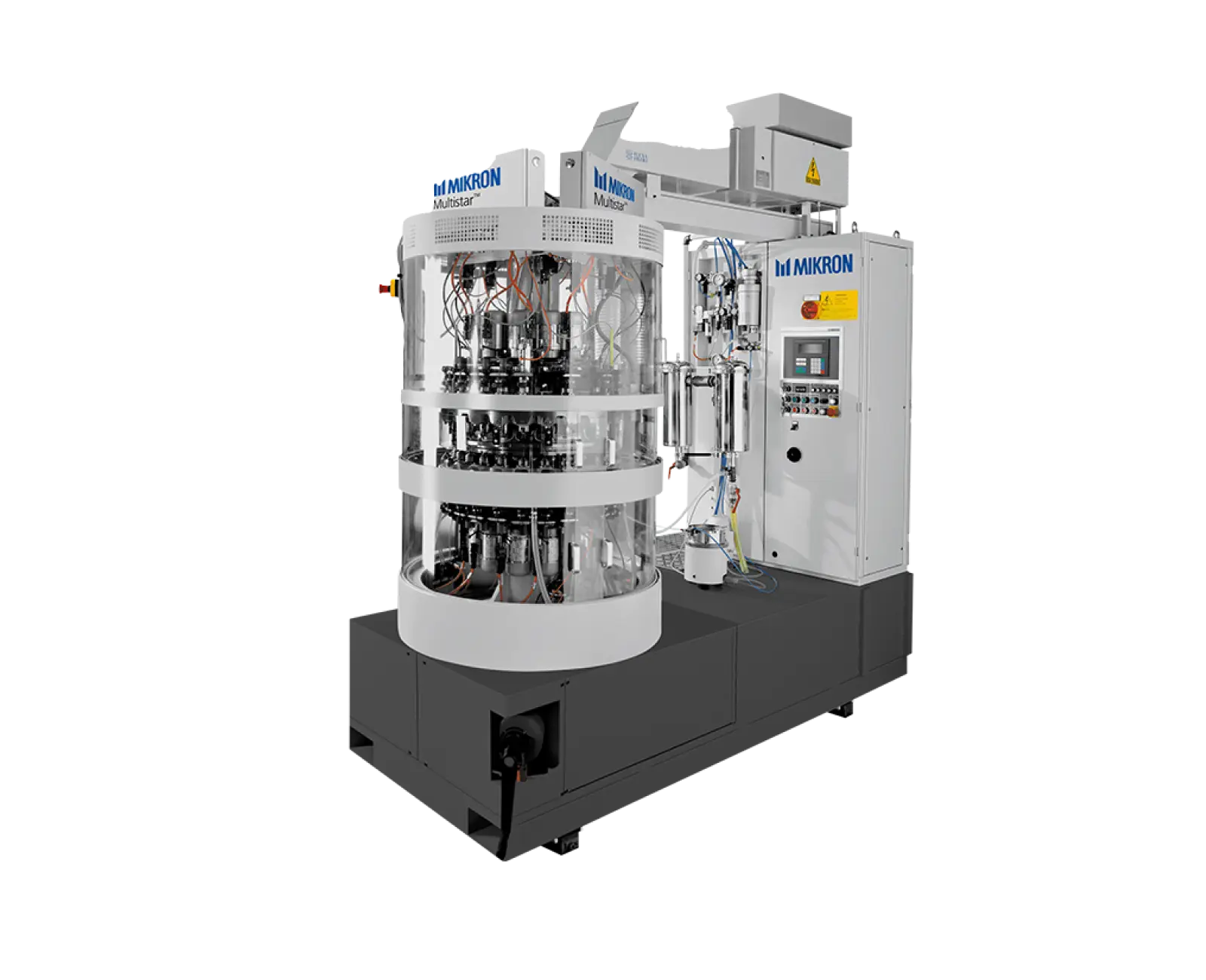

Multistar NX 24

Batch Production Made Easy

Multistar NX 24 is capable of producing complicated, high-precision components in huge quantities with a variety of similar components. If you are max. machining materials like alloy steel, brass, titanium, or aluminium? Then the Multistar NX 24 is the finest option.

Features and Specifications

- Machining units (3 axis and 2 axis): maximal flexibility and versatility

- Deep hole drilling units

- Single axis machining units

- Simple and fast changeover

Edit Content

Mikron NRG-50

Precision meets Flexibility and Productivity.

The rate of innovation is always increasing as a result of rapid technological advancements. The Mikron NRG-50 is a completely modular machine that gives the customer a perfect balance in terms of productivity, flexibility, and cost of ownership.

Features and Specifications

- Full CNC high-productive rotary transfer machine with 12 stations and up to 30 working units machining simultaneously

- For extremely high-precision workpieces up to 80 x 80 x 80mm or cylindrical pieces up to Ø 65 x 100mm

- Complete 6-sided machining possible

In case of any enquiry, leave a message

Address

No. 185/A-1/1, 7th Main Road, Yeshwanthpur Suburb 2nd Stage, Phase -3, Peenya, Bengaluru – 560058

Phone

Fax

G6

The G6’s ideal blend of speed and precision makes it a prime choice for job shops and production lines aiming to enhance their machining capabilities. It offers high material removal rates, superior surface finishes, and optimal production efficiency.

Features and Specifications

- High-performance built-in spindle

- Table moved by swivelling-rotary axes

- Perfect U-shape closed-gantry design

- Linear scales in all guideways

- Rotary table diameter: G6 — 600 mm; G6 MT — 500 mm

- Max table load: G6 — 600 kg; G6 MT — 350 kg (Turning), 500 kg (Milling)

- Max X, Y, Z axis travel: 650, 850, 500 (mm)

- Spindle speed: 20,000 rpm (Standard) or 15,000 rpm (Option)

- Compatible CNC controllers: Fanuc, Heidenhain, Siemens